Materials of VIPs

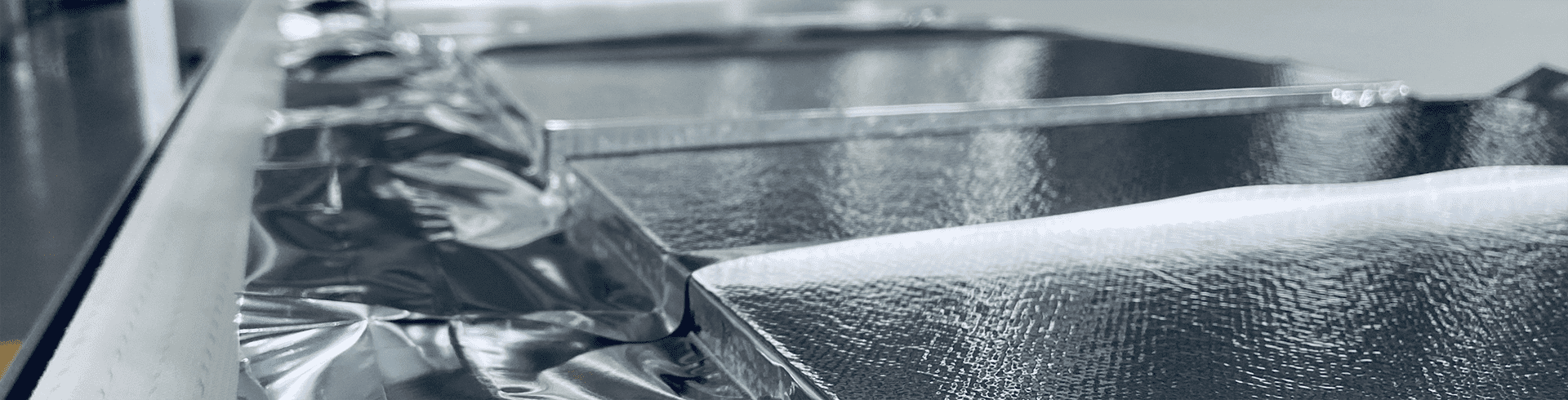

The core material in our vacuum insulation panels (VIPs) is made up of a pressure-resistant compressed plate composed of fumed silica. To create the VIP, the core is first evacuated and then sealed in a high-barrier film using a special technique. Additionally, the special foil utilized in the production of VIPs provides added protection against air and water permeation.